The village of Ilutoro has a new and ultra-modern piggery.

Rotimi Akeredolu, governor of Ondo State in Nigeria, wants to create new jobs and training opportunities as well as alleviate protein deficiency. One means of reaching this goal is the sow farm in Ilutoro, 300 km west of Lagos, which the politician recently inaugurated during a ceremony held for this occasion. All equipment for keeping the sows in a closed system was provided by German pig equipment supplier Big Dutchman.

Shortly before the outbreak of the Coronavirus pandemic, governor Akeredolu and representatives from Big Dutchman signed the contract for the sow farm equipment.

A report about the signing of the contract including a project description is available here.

The first herd with 56 sows recently moved into the new barn. The project managers expect that around 1,000 piglets will be finished until ready for slaughter every year.

Equipment for sow management and pig finishing

Big Dutchman is considered the international market leader for equipment and feeding systems for modern pig production and has been for many years. To keep the distance to customers as short as possible, Big Dutchman has set up a global network of offices and agencies that includes Nigeria: the equipment supplier has been supporting the country’s livestock producers from its location in Lagos for some years now.

Big Dutchman’s scope of services ranges from small to large, fully integrated turn-key farms.

Sow management in Ilutoro | The piglets are born in farrowing frames. The very heavy sows are confined during the suckling period so they do not crush their offspring.

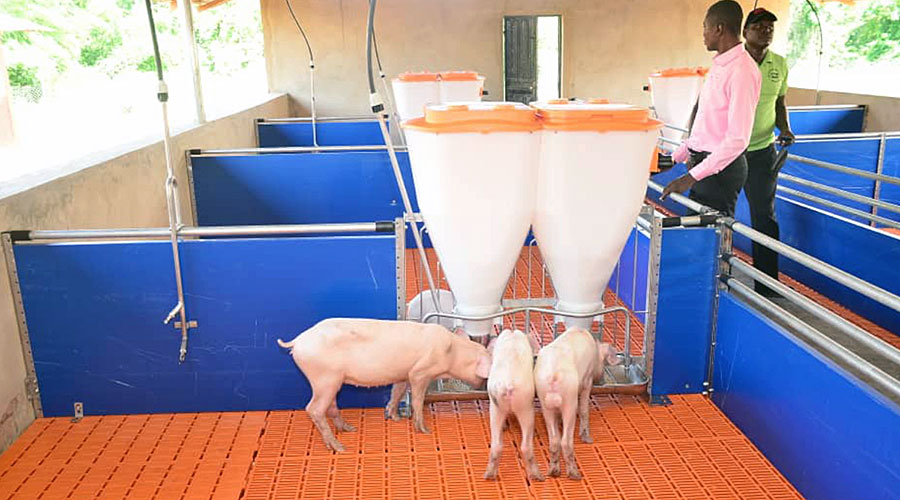

Pig finishing | Pen with piglets and two feeders

Hygiene matters!

Hygiene plays an important role in pig production. The managers of the Nigerian sow farm know this and have therefore selected the corresponding equipment:

- Slatted floors & slurry pits | The pigs step on their faeces so they pass through the floor, and urine drains off, i.e. the pigs have hardly any contact with their excrements; surfaces remain clean ⇒ lower risk of infection

- Reproduction | The sows are exclusively artificially inseminated ⇒ infections caused by mating do not occur

- High-service pen | Sick pigs are separated from healthy ones ⇒ disease transmission is inhibited

- Surfaces | Equipment such as pen panels, feeders or drinkers have smooth, closed surfaces ⇒ thorough cleaning and thus improved hygiene

- Drinking water | The pigs have access to fresh water at all times ⇒ reduced germ count

The pigs’ manure is collected in a pit below the pens. The slurry with its high contents of bound nitrogen, phosphorus, potassium and other nutrients is a very valuable fertiliser that benefits crop growth. It will therefore be spread on the fields and replace chemical fertilisers as nitrogen source in the future.